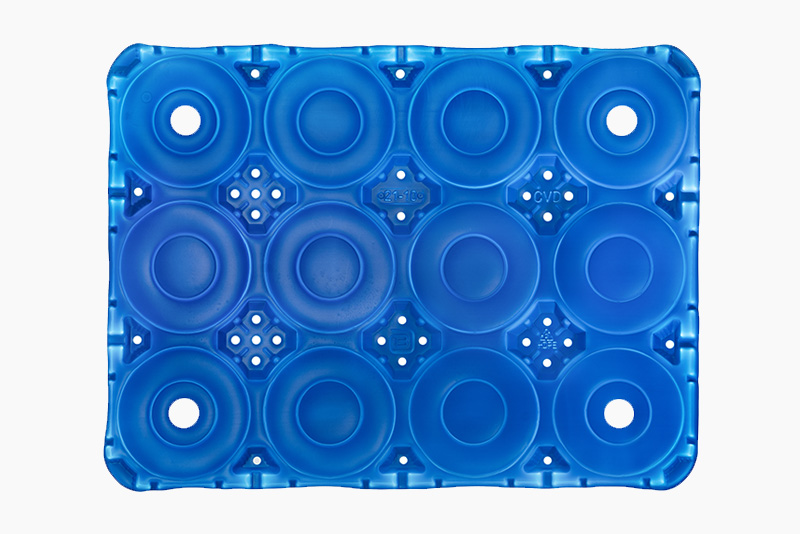

Today, Suzhou vacuum tray manufacturers will provide a detailed introduction to the advantages of vacuum trays in the automotive industry

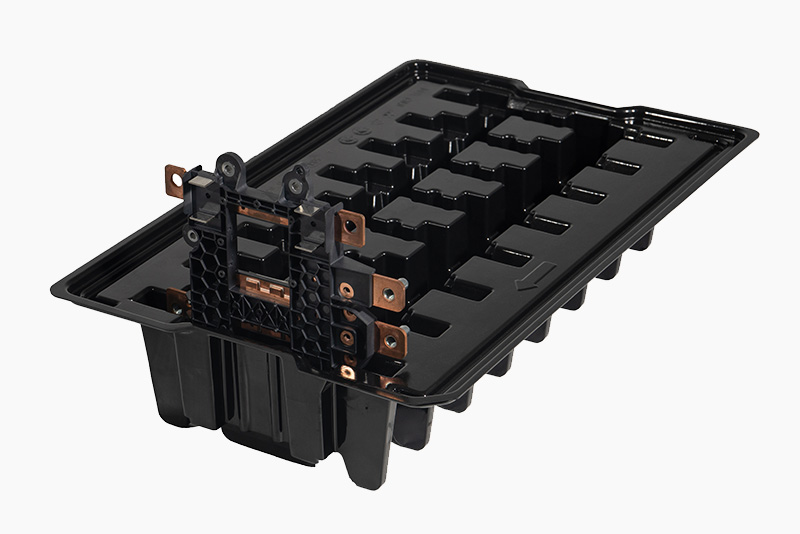

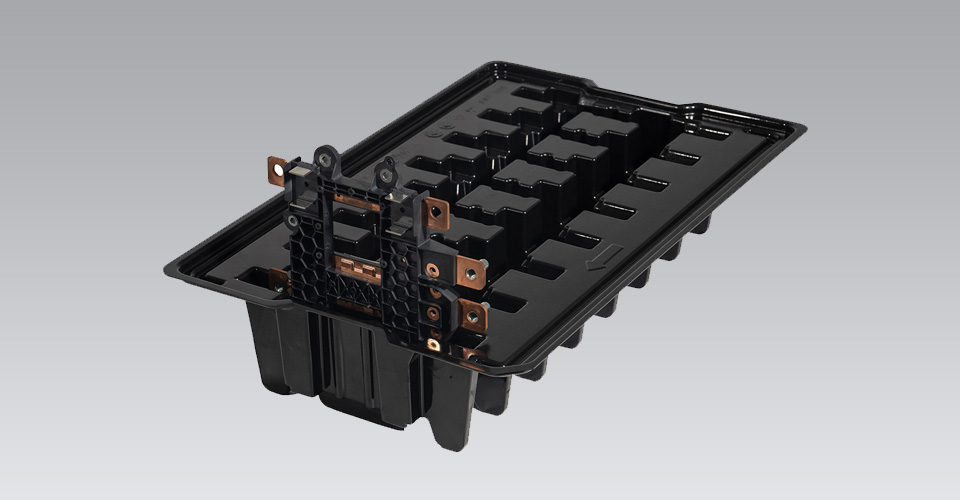

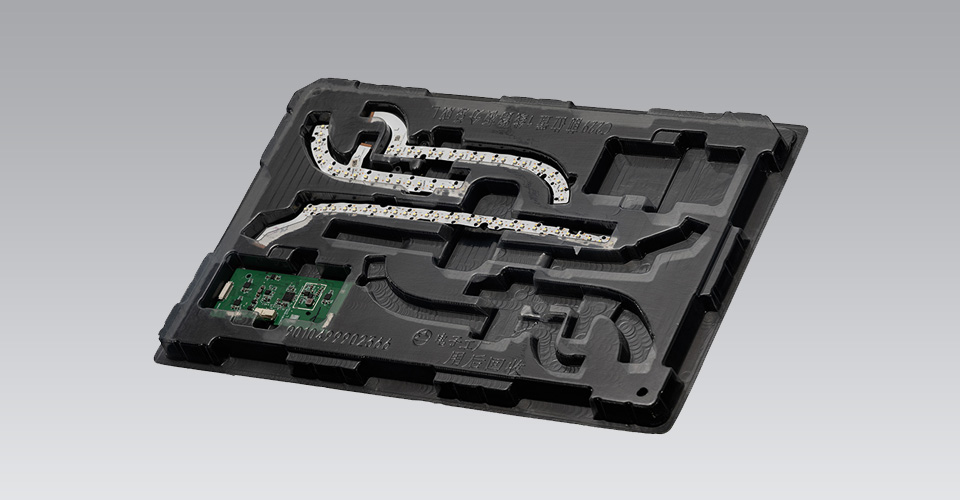

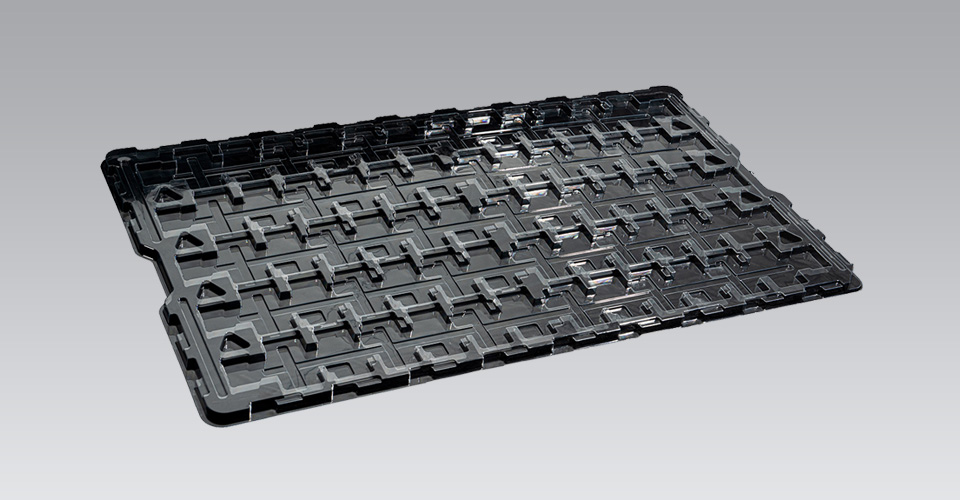

Most of the types of vacuum formed pallets in Suzhou are vacuum formed inner pallets, which are widely used in the automotive industry to protect automotive components and products. The commonly used materials for vacuum tray include PVC, PP, PS, ABS, and sheets with anti-static, flocking, and gold-plated properties. Most of the vacuum trays used in automotive parts are large and thick vacuum trays.

Blister pallets have 6 major advantages, making them favored by suppliers and OEMs in the automotive industry, and their applications are becoming more and more widespread. Let's take a look at these advantages with Xiwode Xiaozhang!

1. Strong environmental performance

Plastic products can all be recycled, and thick sheet vacuum plastic pallets are no exception. After use, vacuum plastic pallets can be recycled, broken into particles, and reused as recycled materials, which to some extent reduces the amount of industrial waste and corresponding waste disposal costs, in line with the national environmental protection concept.

2. Strong durability performance

Vacuum molded pallets are resistant to high temperatures, have strong flexibility, withstand impact and pressure, and have a lifespan approximately 10 times that of wooden pallets. The ultra long service life saves the cost of logistics, turnover, and warehousing for enterprise products.

3. Strong professional performance

The use of vacuum molded pallets in the market is widely welcomed by many enterprises. Thin film vacuum molded pallets can be used in light industries such as medical and cosmetics, while thick film vacuum molded pallets can be used in the automotive machinery industry such as automotive parts and hardware accessories. Different products use different materials of plastic to create exclusive product packaging, with strong professional performance and less likely to cause confusion.

4. Powerful reliability

The thin film vacuum tray is produced according to the mold, and each groove and protrusion is designed according to the appearance of the product, making the product more stable during turnover and transportation, and less susceptible to external damage.

5. Strong transportation performance

Compared to metal and wooden pallets, vacuum molded pallets are lighter in weight, making them easier and more convenient to transport both inside and outside the factory. They also reduce transportation weight and usage costs.

6. Has good adaptability to the development of the times

Blister pallets are non fumigation and inspection free products, and there is no need to go through complicated procedures like wooden pallets in product exports. They can be directly exported to European and American countries. This also makes the use of vacuum molded pallets unrestricted by industry and geographical limitations.

Phone

Phone WeChat

WeChat