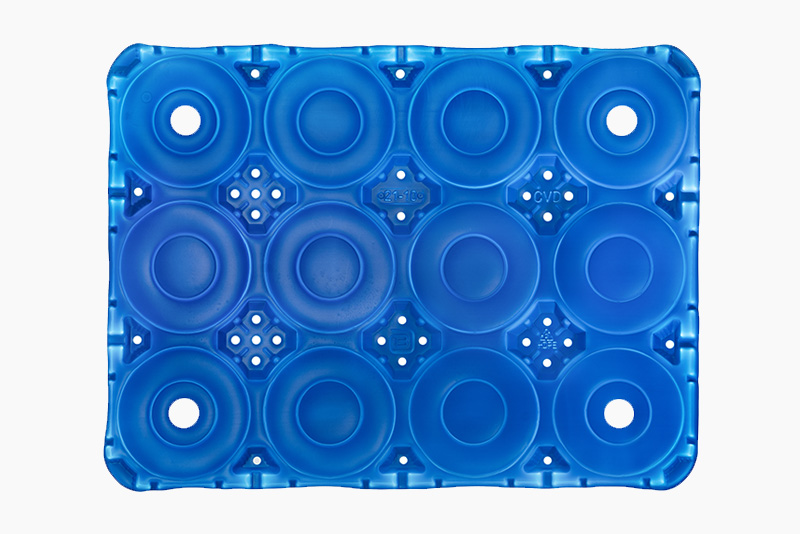

Today, the Suzhou automobile gearbox vacuum tray manufacturer will provide a detailed introduction to "automobile gearbox vacuum tray, automobile wheel hub vacuum tray"

The automobile gearbox is an important component of a car, which converts the output of the engine into the speed of the wheels, thereby controlling the acceleration and deceleration of the car. Gearboxes are generally divided into manual transmissions and automatic transmissions. Manual transmissions require the driver to manually adjust the D position to change the vehicle's driving speed, while automatic transmissions use electronic control systems to control the D position and change the vehicle's driving speed.

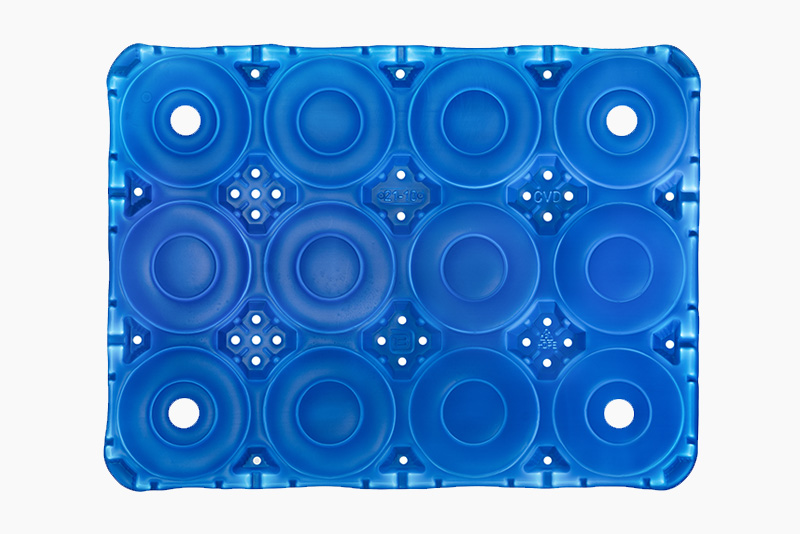

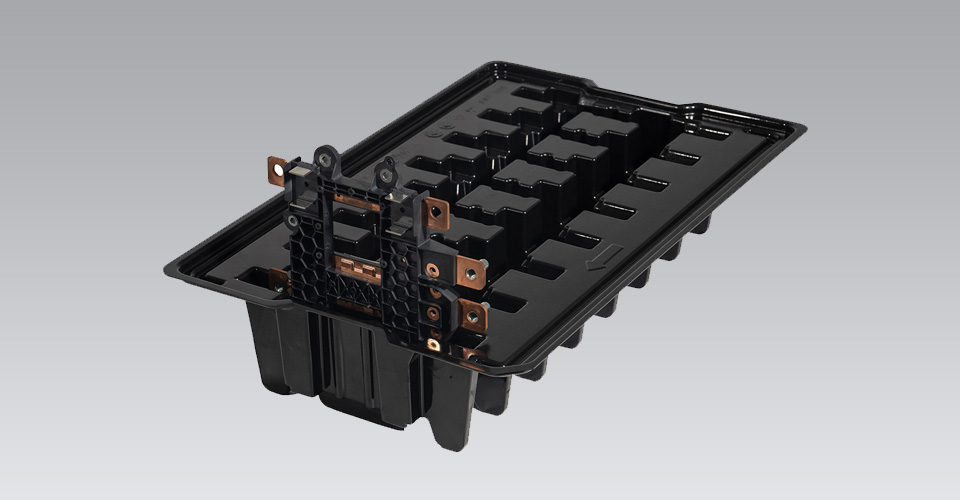

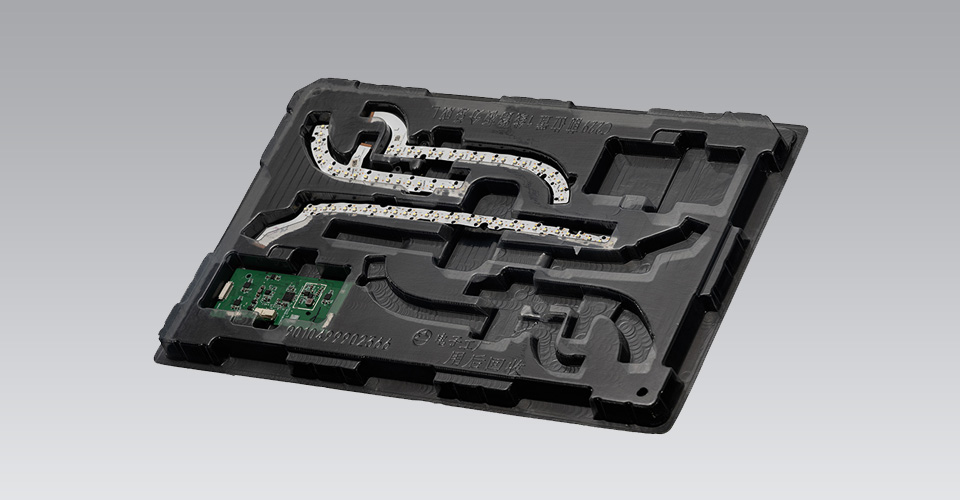

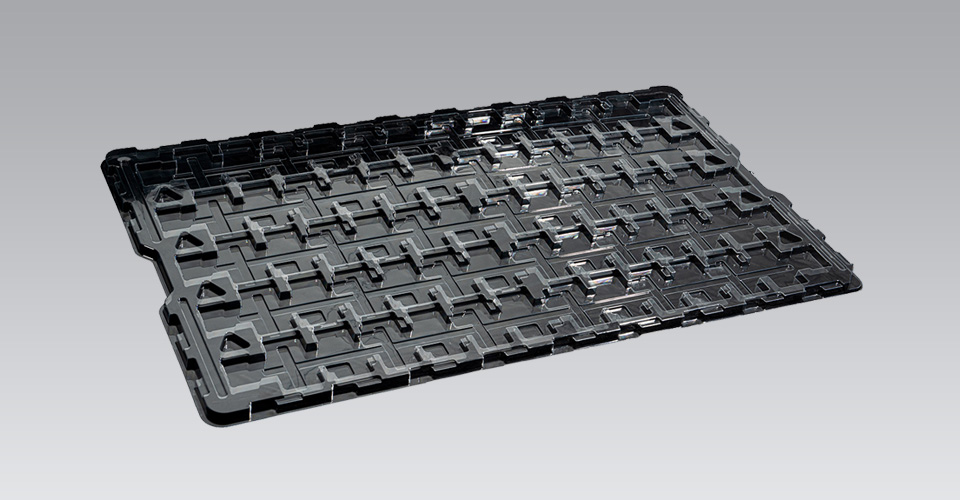

Automotive transmission vacuum tray is a plastic tray with a special shape used for storing, transporting, and handling automotive transmission parts. They are usually made of high-strength high-density polyethylene (HDPE) or polypropylene (PP), which can effectively protect the internal parts of the gearbox, help the car gearbox operate better, prevent parts from being affected by the external environment, prevent parts from friction and wear, ensure the safety and reliability of parts, and improve the service life of the gearbox.

ABS+PET composite material has excellent comprehensive performance and is a commonly used material in the current vacuum forming process. The vacuum forming tray for automotive components requires the use of ABS+PET board raw materials to improve the bearing strength. The characteristics of ABS determine the tray; The PET material on the surface of the board is not too thick due to cost and strength factors. After vacuum stretching, the TPU thickness on the surface is less than 0.5mm, and some parts are even thinner;

With the development of the logistics industry, customers also have special requirements for the materials of products. After ABS+PET composite materials are formed in vacuum molding molds, the PET surface may exhibit surface adhesion ripples, whitening, cracking, and pitting due to attachment to the mold, which affects the quality of the formed products. How to effectively solve these problems, including the following steps:

1. Put the ABS+PET composite material into an oven for baking, with a baking time of 10-14 hours and a baking temperature of 60-80 ℃;

2. Put the baked ABS+PET composite material into the vacuum molding mold for molding operation. The mold needs to be pre heated to control the operating temperature of the mold at 60-80 ℃;

3. Heat and soften the formed product, so that the PET surface of the product is heated in a temperature environment of 90-110 ℃.

By pre baking the ABS+PET composite material in an oven to remove moisture and moisture from the material, then heating the mold, and finally heating the formed product, the product can be extended through contact with room temperature during the softening process. This effectively solves surface defects such as bonding ripples, whitening, cracking, and pitting on the PET surface.

The surface of the automotive wheel hub vacuum tray is made of PET material, which can be cleaned at high temperature of 80 ℃ to ensure the normal use of the product. It solves the problem of no debris generated by friction between the parts and the automotive wheel hub vacuum tray during recycling and transportation. It can also clean the oil stains and similar substances adhered to the vacuum tray at high temperature.

Phone

Phone WeChat

WeChat