SEVOD Professional Technical Team

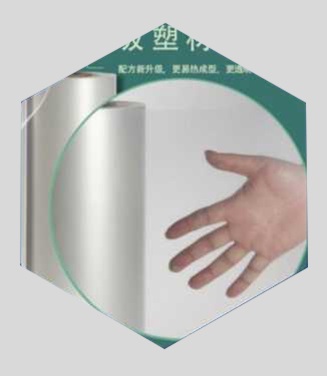

Our company's research on new materials complies with international environmental standards and has deep cooperation with Suzhou University. Through professional team cooperation, we conduct formula analysis, composition testing, and performance improvement, and develop multiple new types of materials that are earthquake resistant, wear-resistant, powder resistant, cold resistant, high temperature resistant, high elongation, and easy to clean;

Biodegradable new materials can improve the tensile and co extrusion properties of hot formed materials, enhance transparency, sealing strength, enhance tensile strength, crack resistance, and other stable properties; Improving molecular weight distribution and extrusion rheological properties, plastic modification, and coating technology for vacuum forming materials;

We have a team of highly skilled design and development personnel, consisting of industry design engineers, process engineers, and molding material engineers who have been in the industry for many years, responsible for our core research and development design tasks;

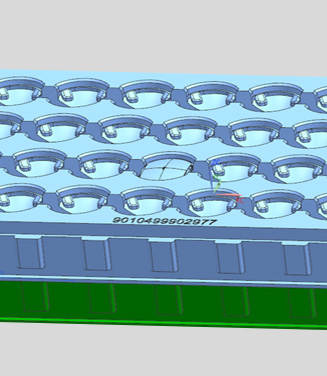

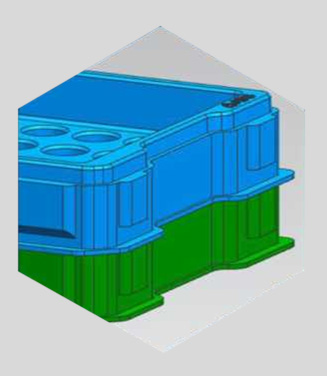

The design of new materials and products will be comprehensively evaluated based on the requirements of product application scope, material characteristics, material thickness, weight, external dimensions, product shrinkage rate, deformation, load-bearing capacity, and potential problems in later use, and a plan will be designed;

In production

Dust free, non corrosive gas, temperature controlled, humidity controlled, and anti-static; Strictly follow the 5S standard in the workshop

The process and process of the system

From evaluation, design to mold opening, from material selection, sampling to mass production and shipment, all stages are controlled

Rich production experience

A team led by outstanding technical talents in various fields such as machinery and automation, as well as technical personnel with more than 20 years of peer experience, controls

Advanced equipment

Large scale positive and negative pressure integrated machines, thick film vacuum molding machines, high-speed forming machines, cutting machines, engraving machines, etc

"Incoming inspection"

"Shipping inspection"

"24-hour after-sales service"

"A sound IS09001 quality management system"

"Sampling inspection of each production process"

"Strict control of product quality"

"Based on customer requirements"

"Based on customer satisfaction"

Sea, land, and air coordination to achieve multi location distribution, save transportation capacity, save costs, and reduce costs.

By managing multiple warehouses, multiple shippers, and multi-level storage locations, we aim to save time and costs for our customers.

Meeting the needs of different customers, based on service, seeking survival through quality, seeking development through technology.

Large layout cutting machine

Thick film vacuum molding machine

Positive and negative pressure integrated machine

High speed servo machine

Finished product warehouse placement area

Mold placement area

Vacuum disc cleaning and dust removal machine

Dual station cutting machine