Thick sheet vacuum forming refers to the process where the thickness of the raw material exceeds 2mm and cannot be vacuum formed on fully automatic machines. It is necessary to use specialized semi-automatic vacuum forming equipment for thick plates for processing and production. Thick sheet vacuum forming products generally have the characteristics of large area, high height, and thick material, which cannot be vacuum formed.

Today, Suzhou vacuum box manufacturers will provide a detailed introduction to "the use and characteristics of thick sheet vacuum plastic products in the automotive industry"

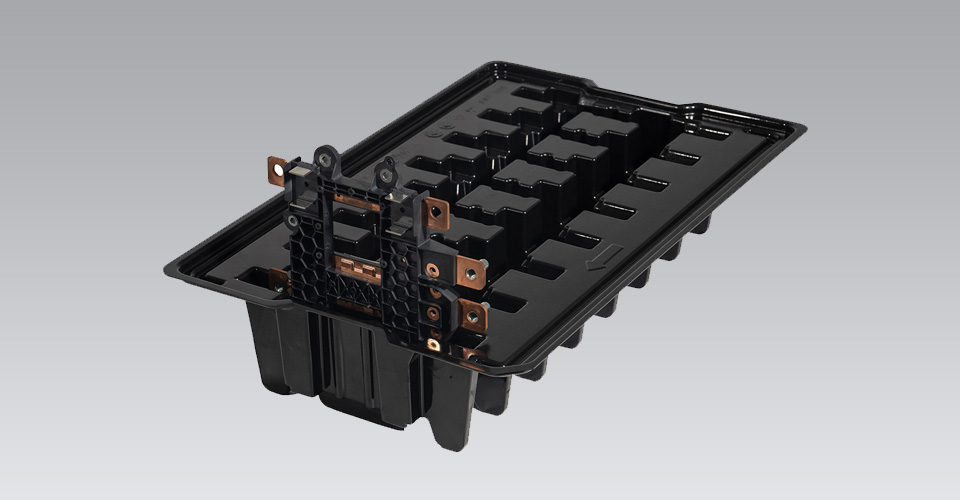

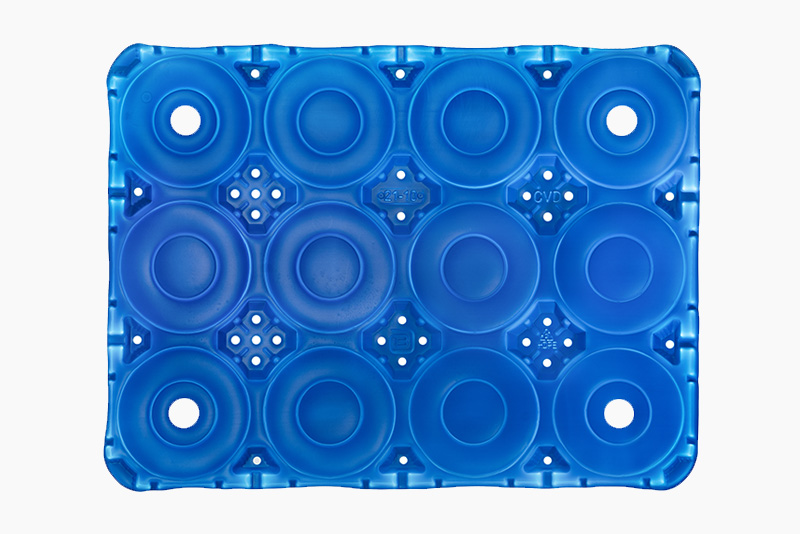

1、 Suzhou vacuum molded pallets are used for automotive products.

1. High density polyethylene material: has good heat resistance, low temperature, chemical stability, strong rigidity, good toughness, and resistance to environmental stress. Scope of application: Special packaging for suction cups, fuel tanks, and most automotive parts.

2. ABS material: It has good impact resistance, heat resistance, low temperature resistance, chemical corrosion resistance, and excellent electrical properties. Compared with HDPE, it is easy to form, has stable dimensions, good surface gloss, and better load-bearing capacity. Scope of application: Automotive, electronic, office, and communication equipment.

3. ABS+TPU material: In the production process of ABS board, a new type of TPU film is covered on the surface. The product has both the excellent mechanical properties of ABS and the high wear and tear resistance of TPU. The cost of this type of material is 2-3 times that of ordinary materials. Due to the high cost of this material, there are certain limitations in its use. TPU characteristics: It has excellent wear resistance, more than five times higher than natural plastic wear resistance, and is one of the selected materials for product wear resistance. It is more tear resistant than ordinary plastic.

Application scope: Mainly used for automotive interiors, components with high requirements, such as engines, transmissions, etc.

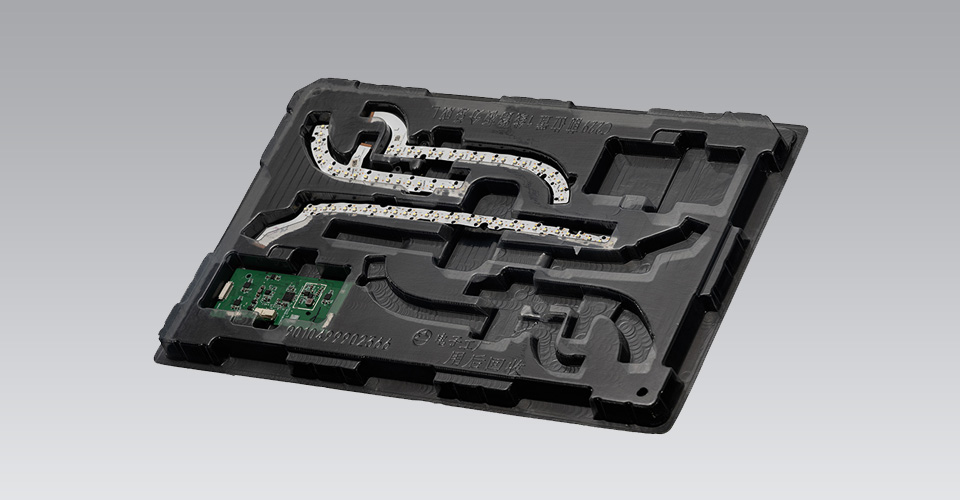

2、 The characteristics and uses of thick film vacuum molding.

Vacuum forming is a plastic processing technology, which mainly involves heating and softening flat plastic hard sheets, using vacuum adsorption on the surface of molds, cooling and forming them. It is widely used in industries such as plastic packaging, lighting, advertising, and decoration. In general, the thickness of thick film vacuum molding ranges from 0.14 to 8.0mm - mainly including ABS thick film vacuum molding, PC thick film vacuum molding, PVC, PP, PS (HIPS), PET (including APET and PETG), and various injection molding types of vacuum molding products with different materials and effects. They are mainly used for refrigerator liners, advertising light boxes, product display racks, pet cage chassis, rear shell of rear projection TVs, and various mechanical panels, and can replace injection molding products.

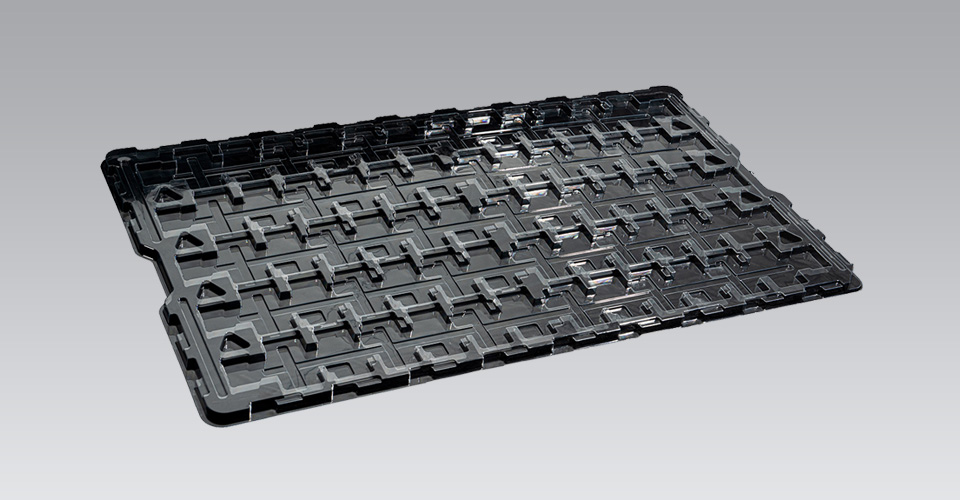

Features of thick sheet vacuum tray:

Low mold cost (only 1/20 of injection molding), short production cycle, and short mold development time (usually 3-5 days).

Why classify the types of materials? The main consideration is that there are certain differences between the materials used in ordinary thin vacuum molding and special thick film vacuum molding, and PVC, PP, PS, and PET occupy a place in these two types of vacuum molding products!

Thick film vacuum box usage:

1. PVC hard sheets have moderate toughness and are not easy to burn. When burned, chlorine gas is produced, which has a certain impact on the environment. PVC is easy to heat and can be sealed by sealing machines and high-frequency machines. It is the main raw material for transparent vacuum products.

2. PS hard sheets have low density, poor toughness, and are prone to combustion. When burned, they produce styrene gas (which is a harmful gas), so they are generally used to manufacture various industrial vacuum pallets.

3. PET hard sheets have good toughness, high transparency, easy combustion, and no harmful gases during combustion.

Phone

Phone WeChat

WeChat