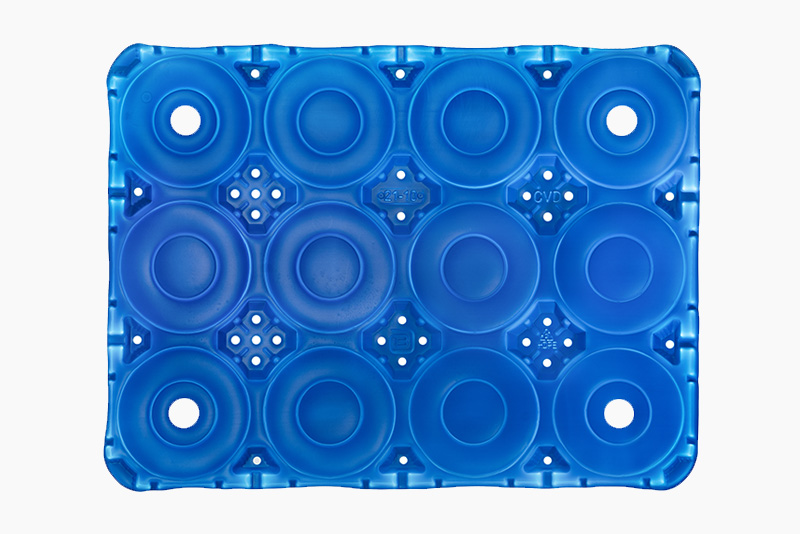

Today, Suzhou vacuum box manufacturers will provide a detailed introduction to the "automotive thick film vacuum molding process"

1、 Material preparation - Select the corresponding sheets and molds according to the requirements on the construction order.

1. Collect relevant automotive thick film vacuum molds and clean and lubricate them

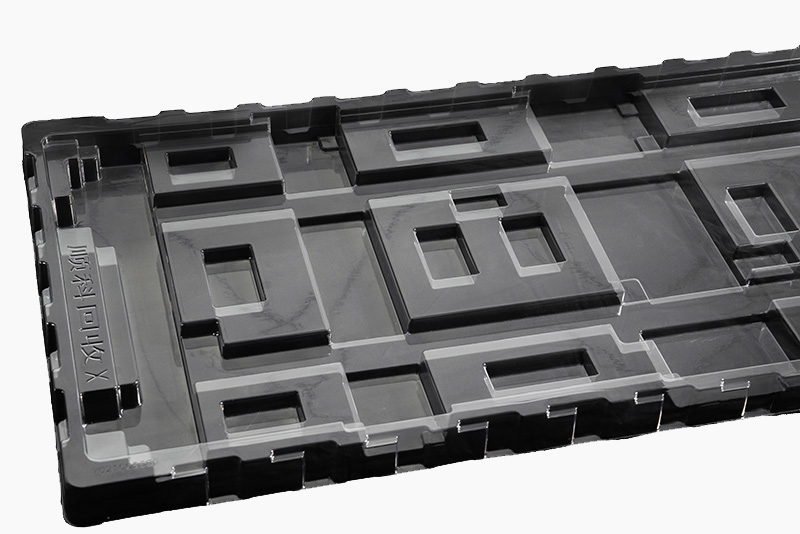

2. Receive relevant automotive thick film vacuum plastic sheets, pre inspection materials, external dimensions, thickness, weight (quantity)

2、 Mold installation - install relevant molds, preheat the plastic suction machine, and check the suction of the vacuum pump. After pre heating to the specified temperature, the product shall be debugged until it meets the requirements of the construction order.

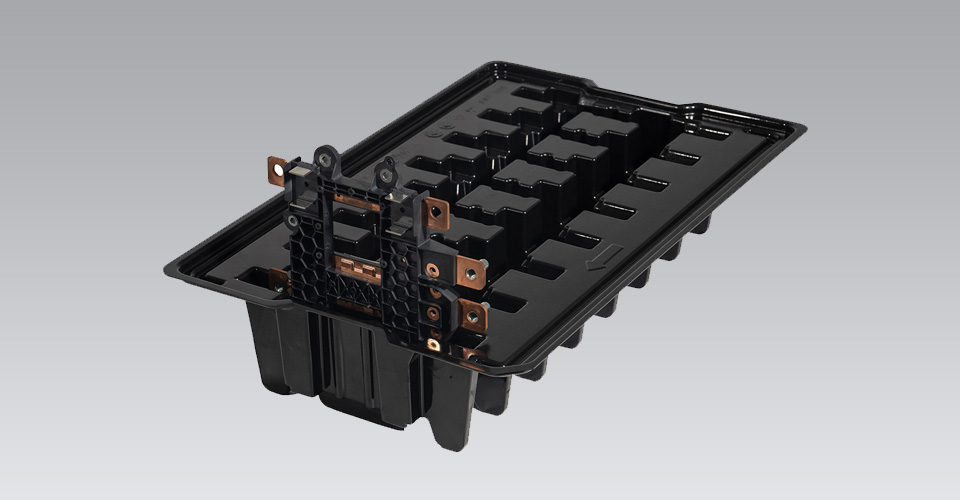

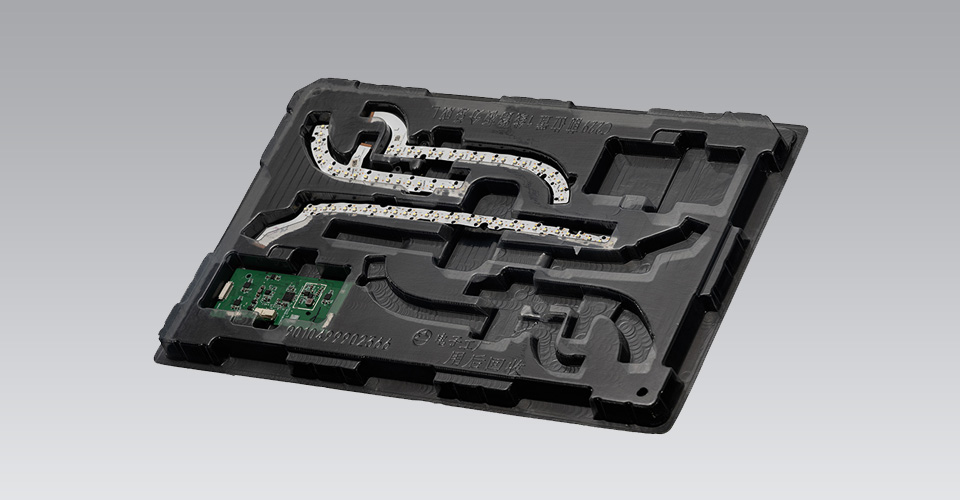

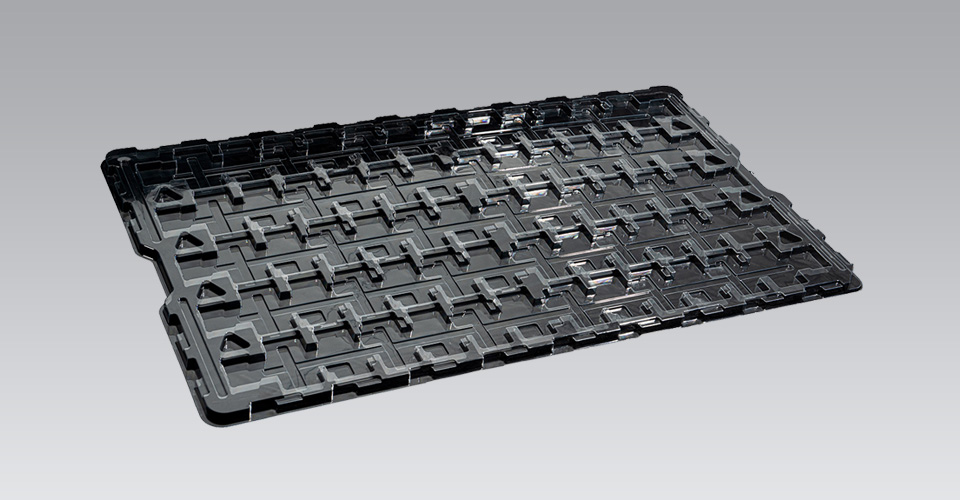

1. Vacuum forming production - The sheet material is installed into the feeding mechanism of the vacuum forming machine for normal production (softening, vacuum forming, forming), where heating softens vacuum forming for 3 seconds, cooling breaks for 12 seconds, and semi-finished products are stacked in designated positions. Conduct quality inspection of semi-finished products according to the construction order.

2. Semi finished product punching - Install corresponding punching molds and debug them. After passing the inspection, the semi-finished products are punched and the waste materials are placed in the designated basket. When stacking thick film vacuum boxes for automobiles, it is necessary to ensure that the products are clean and undamaged, and the quality of the finished products is inspected according to the construction order.

3. Packaging of finished products using vacuum molded thick sheet vacuum molded pallets for automobiles - using cardboard boxes for packaging, lined with moisture-proof and dust-proof box bags, and packing qualified products in boxes according to the quantity specified in the construction order. Fill in all the contents of the certificate of conformity (product name, specifications, weight, grade, batch number, roll number, shift, date).

4. Product warehousing - enter the warehouse according to the total quantity specified in the construction order.

5. Dismantling the thick film vacuum molding mold for automobiles - first cut off the power, wait for the heating components of the vacuum molding machine to completely cool down, then dismantle the entire set of molds, clean and apply anti rust agents, check for defects, and store them in the warehouse for retention. Keep a record of the mold usage.

6. Cleanliness and Hygiene - During the production process, keep the equipment clean around, carefully keep production records, and carry out handover work. The production content, quality requirements, and product stacking location of the shift must be explained 15 minutes in advance.

Phone

Phone WeChat

WeChat